Wireless Temperature Monitoring

Optimize temperature control in healthcare, food, pharmaceutical, and logistics operations with Seemoto’s real-time wireless monitoring.

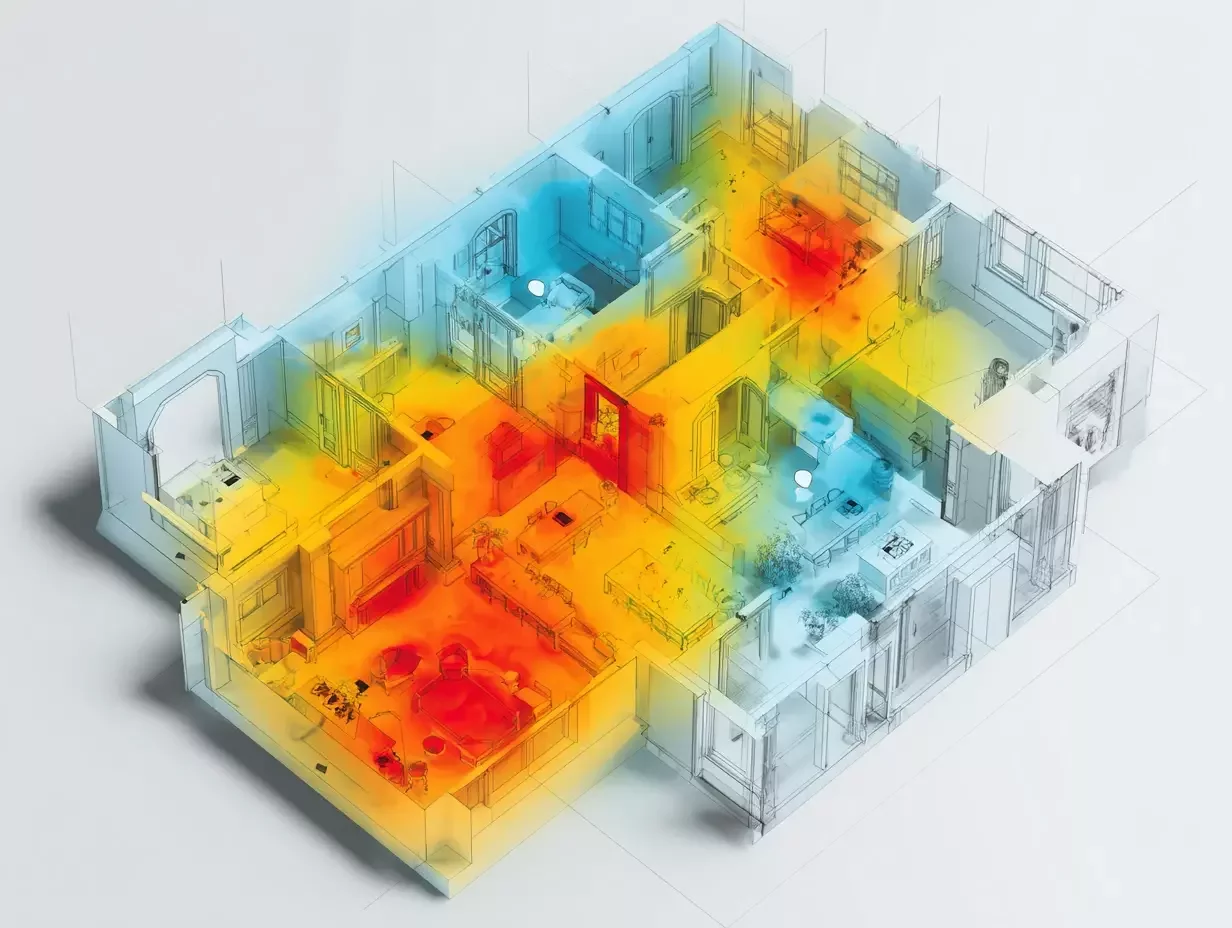

Automated Temperature Mapping with Seemoto Wireless Sensors

Accurate temperature mapping is essential for validating and maintaining controlled environments such as warehouses, cold rooms, delivery vehicles, and laboratory storage. Traditional wired systems often demand complex setup, manual validation, and repeated recalibration. Seemoto eliminates these challenges with a fully wireless, automated mapping solution designed for precision, compliance, and ease of use.

Seemoto’s system captures detailed temperature and humidity profiles across any monitored area revealing gradients, hotspots, and airflow variations that can affect product quality or regulatory compliance. Installation is fast and scalable, with no wiring or IT integration required. Real-time data, automated reports, and cloud-based access make Seemoto ideal for both validation mapping and long-term continuous monitoring, supporting compliance with EN12830, GDP, GMP, and FDA 21 CFR Part 11 standards.

Core Solution Benefits

Seemoto’s wireless monitoring solution is designed for effortless deployment and reliable performance. Installation is fast and requires no wiring—sensors operate independently, while gateways simply plug in for power. All collected temperature and humidity data is automatically transferred to Seemoto Cloud, where it is securely stored for five years and remains fully compliant with international standards.

Users receive instant alerts whenever temperature or humidity levels deviate from set limits, ensuring proactive response to any issue. The system works seamlessly across refrigerators, freezers, warehouses, transport vehicles, and production areas, providing full visibility of environmental conditions in real time. With automated reporting, accurate mapping, and centralized cloud access, Seemoto transforms compliance monitoring into a simple, scalable, and maintenance-free process.

Want to see how this works in your facility? Let’s schedule a short demo.

Seemoto Wireless Monitoring Use Cases

Commonly asked questions

Let's Design Your Monitoring Setup

Whether you're monitoring a cold room, a pharma trailer, or a mobile cooler, Seemoto brings real-time insights and automated compliance to every part of your cold chain.