Audit-Ready Temperature Validation Without Operational Disruption

Wireless Temperature Mapping by Seemoto enables regulated and temperature-sensitive operations to validate, document, and maintain thermal uniformity across facilities, storage areas, and transport environments – without cabling, manual data handling, or complex IT projects.

Designed for GDP, GMP, HACCP, EN 12830, and FDA-regulated environments, Seemoto combines wireless sensors, automated data capture, and cloud-based reporting to simplify both initial validation and ongoing compliance.

The Challenge

Traditional Temperature Mapping Creates Risk and Overhead

Organizations performing temperature mapping still face recurring challenges:

Manual logger setup and retrieval slows validation projects

Paper-based or fragmented data complicates audits

Repeated re-mapping increases cost and operational downtime

Limited visibility between mapping cycles creates compliance gaps

Validation and monitoring often require separate systems

In regulated environments, these inefficiencies translate directly into audit risk, resource drain, and delayed operations.

The Seemoto Solution

Fully Wireless, Automated Temperature Mapping

Seemoto replaces manual mapping processes with a wireless, cloud-connected validation workflow that delivers accurate results faster and with lower effort.

What makes Seemoto different:

Fully wireless temperature and humidity sensors

Battery-powered devices with no fixed cabling

Automated data logging and secure cloud storage

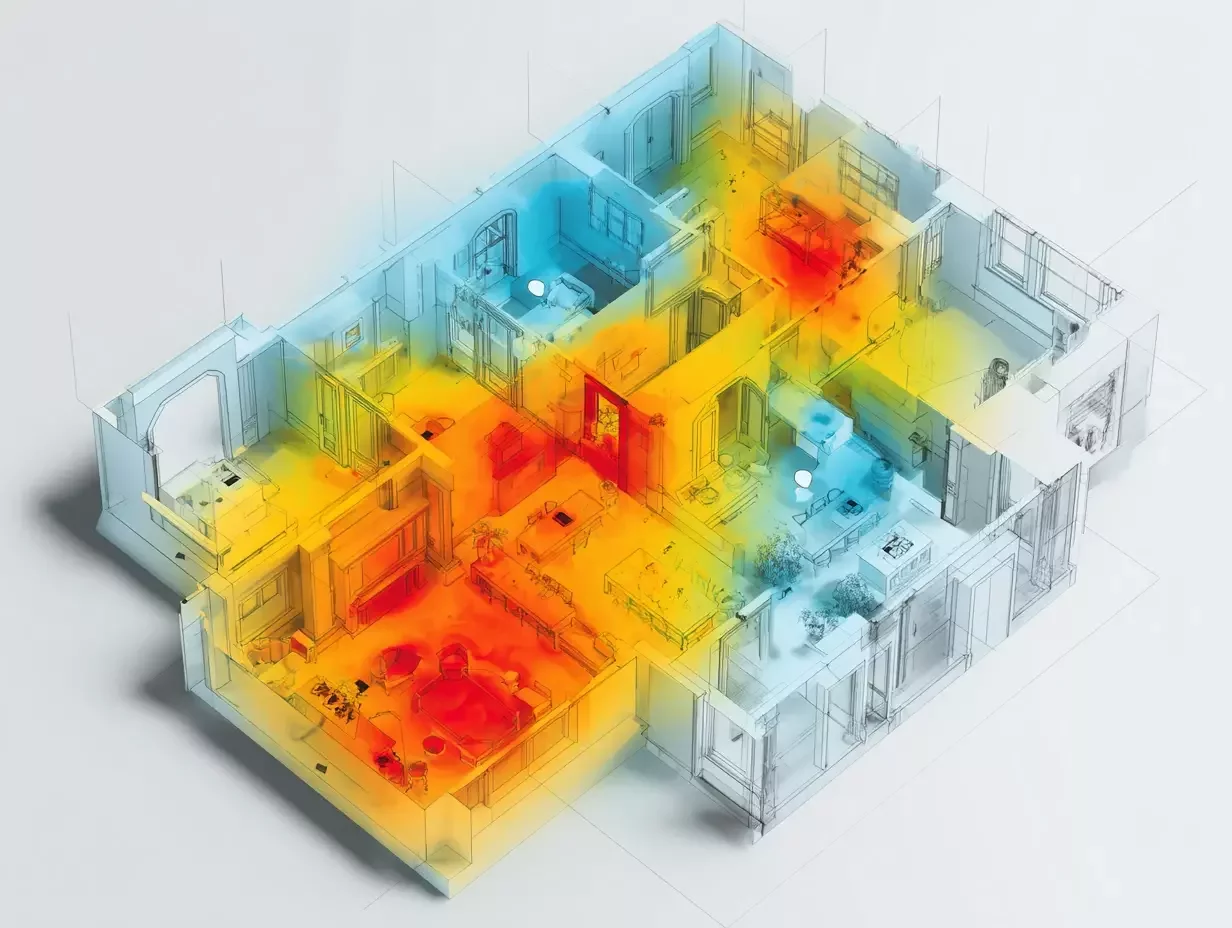

Visual dashboards showing temperature distribution and gradients

Audit-ready reports generated directly from collected data

Seemoto supports both one-time validation studies and continuous mapping strategies, allowing organizations to move seamlessly from validation to long-term monitoring.

Want to see how this works in your facility? Let’s schedule a short demo.

Compliance and Regulatory Confidence

Seemoto temperature mapping supports compliance with key international standards and guidelines, including:

GDP and GMP requirements

HACCP documentation and traceability

EN 12830 temperature recording

FDA 21 CFR Part 11 ready reporting workflows

ISO-aligned data integrity and audit trails

All collected data is securely stored in the Seemoto Cloud, maintaining a complete historical record for audits, inspections, and quality reviews.

What You Can Validate and Map

Seemoto enables temperature mapping across a wide range of controlled environments:

Cold rooms and freezers

Warehouses and distribution centers

Laboratories and cleanrooms

Pharmaceutical and biotech storage

Transport vehicles and mobile storage units

Refrigerated retail and food production areas

Temperature, humidity, and optional environmental parameters are captured continuously, revealing hot spots, cold zones, airflow effects, and stability trends.

Professional Services

Seemoto offers professional services to support validation projects when internal resources are limited or when regulatory confidence is critical:

Temperature mapping study planning

Sensor placement guidance and risk-based design

Remote or on-site validation support

Documentation review and audit preparation

Transition from mapping to continuous monitoring

These services can be used project-based or ongoing, depending on organizational needs.

Core Benefits for Decision Makers

For Quality & Compliance Teams

Audit-ready documentation with minimal manual effort

Clear deviation records with timestamps and corrective actions

Reduced risk of missing or incomplete validation data

For Operations & Facility Management

Fast deployment without IT or infrastructure changes

Minimal disruption to daily operations

Scalable mapping across multiple sites

For Management & Procurement

Lower validation costs over time

Reduced dependency on manual labor and consultants

One platform for mapping and ongoing monitoring

Industries and Use Cases

While this is a solution-focused page, Seemoto temperature mapping is commonly used in:

Pharmaceutical and biotech operations

Cold chain logistics and transport

Food production and perishable storage

Healthcare and laboratory environments

Retail refrigeration and distribution

Industrial process areas

Each industry benefits from the same core outcome: validated temperature control with less effort and higher reliability.

From Mapping to Continuous Monitoring

Seemoto allows organizations to extend temperature mapping into long-term continuous monitoring, using the same wireless infrastructure.

This ensures:

Continuous compliance between validation cycles

Immediate alerts during temperature excursions

Long-term trend analysis and early risk detection

Mapping becomes part of an ongoing quality strategy rather than a recurring operational burden.

Seemoto Wireless Monitoring Use Cases

Commonly asked questions

Let's Design Your Monitoring Setup

Whether you're monitoring a cold room, a pharma trailer, or a mobile cooler, Seemoto brings real-time insights and automated compliance to every part of your cold chain.