Automated Reporting. Audit-Ready by Design.

Seemoto’s Audit & Reporting Tool transforms raw monitoring data into clear, compliant, and inspection-ready documentation with minimal effort.

All measurements, alerts, and events are automatically recorded in the Seemoto Cloud and can be exported instantly as structured audit reports.

Designed for regulated environments across pharmaceuticals, food, healthcare, logistics, and industrial operations, the tool eliminates manual reporting, reduces audit risk, and ensures data integrity at every stage.

One platform. One source of truth. Always audit-ready.

Built for Regulated Operations of Any Scale

From single-site operators to global organizations, Seemoto centralizes all monitoring records into a secure, cloud-based audit repository.

The Audit & Reporting Tool supports:

Temperature and condition monitoring records

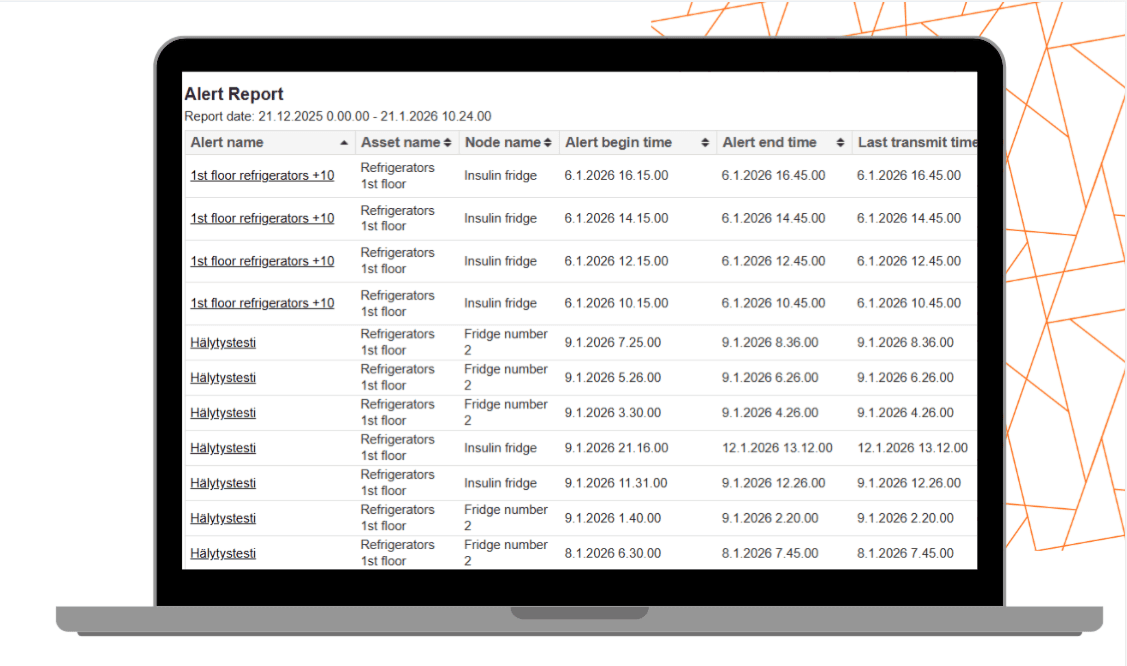

Alert and deviation history

Time-stamped measurements and system events

Long-term data retention aligned with regulatory requirements

All data is continuously available, searchable, and exportable across locations, devices, and time ranges.

No spreadsheets. No paper logs. No gaps.

One-Click Audit-Ready Reports

Generate professional audit documentation in seconds.

Seemoto allows users to:

Export reports in PDF or CSV

Select custom time ranges

Filter by location, sensor, asset, or alarm

Include min/max/average values, deviations, and timestamps

Reports are structured to support internal audits, customer reviews, and regulatory inspections without additional formatting or manual work.

Full Traceability & Data Integrity

Every measurement captured by Seemoto is:

Time-stamped

Tamper-resistant

Linked to its source sensor and location

Stored securely for up to five years

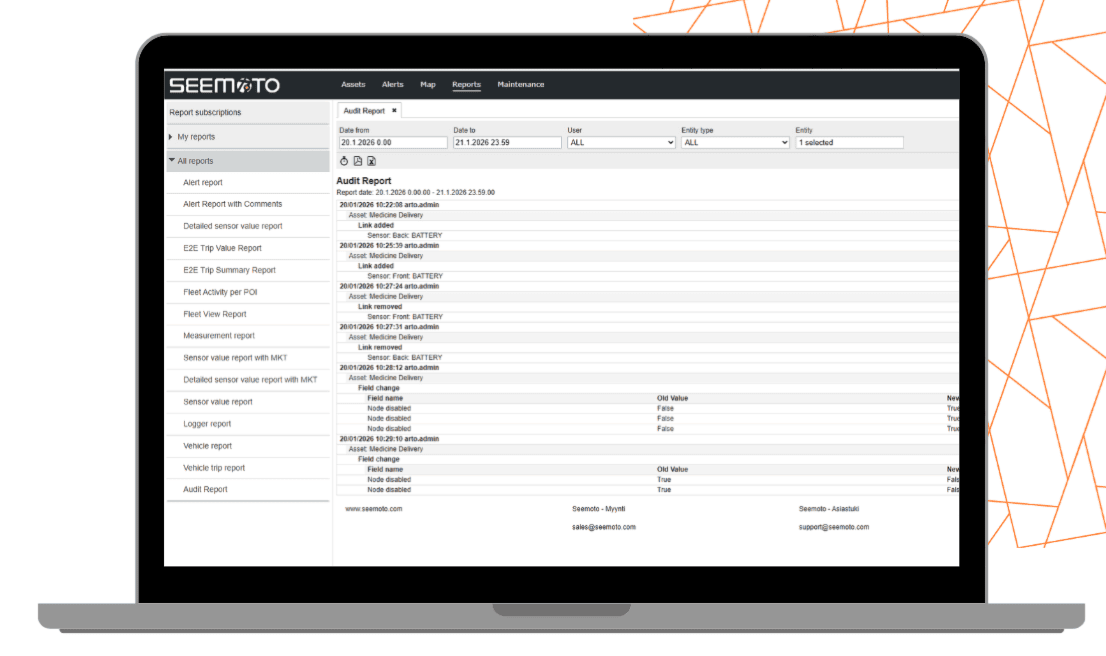

The Audit & Reporting Tool maintains a complete audit trail covering:

Sensor readings

Alarm triggers and acknowledgements

System status changes

User actions (where applicable)

This ensures full traceability aligned with EN12830, GDP, GMP, HACCP, and FDA 21 CFR Part 11–supportive workflows.

Works Seamlessly with Seemoto Monitoring

The Audit & Reporting Tool is fully integrated with:

Real-time monitoring

Mobile and fixed sensors

Gateways (GSM by default, Ethernet where required)

Seemoto dashboard and mobile app

No separate systems. No data duplication.

Everything flows automatically into a single reporting environment.

Why Seemoto Audit & Reporting

Centralized cloud-based reporting

One-click exports (PDF / CSV)

Long-term secure data retention

Audit-ready structure by default

Reduced manual workload

Trusted across regulated industries

Designed to Reduce Audit Risk

Manual logging and fragmented data are common causes of audit findings.

Seemoto removes these risks by automating documentation at the source.

Key risk-reduction capabilities:

No missing measurements

No handwritten records

No manual data transfer

No inconsistent report formats

Auditors see consistent, chronological, and verifiable records every time.

Actionable Insights, Not Just Reports

Beyond compliance, the Audit & Reporting Tool supports operational improvement.

Users can:

Identify recurring deviations

Compare performance across sites

Analyze trends over time

Support corrective and preventive actions (CAPA)

This turns reporting from a compliance burden into a decision-support tool for quality, operations, and management teams.

Typical Use Cases

Pharmaceutical & Healthcare Audits

Temperature compliance for medicines, vaccines, blood, and samplesFood Safety & HACCP Documentation

Automated records for storage, production, and distributionWarehouse & Logistics Inspections

Proof of compliance across multiple zones and sitesCold Chain & Transport Validation

Exportable reports for routes, storage periods, and handoversInternal Quality Reviews

Performance benchmarking and continuous improvement

Commonly asked questions

Let's Design Your Monitoring Setup

Whether you're monitoring a cold room, a pharma trailer, or a mobile cooler, Seemoto brings real-time insights and automated compliance to every part of your cold chain.