Continuous, compliant monitoring for critical cold and ultra-low temperature environments

Cold storage and deep freezer environments protect high-value, temperature-sensitive products such as pharmaceuticals, vaccines, biologics, laboratory samples, food products, and industrial materials. Even short temperature excursions can result in product loss, compliance breaches, or operational downtime.

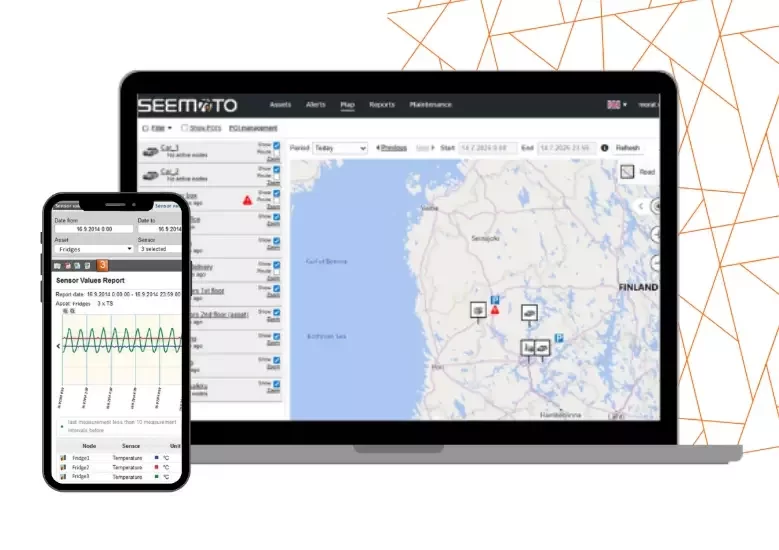

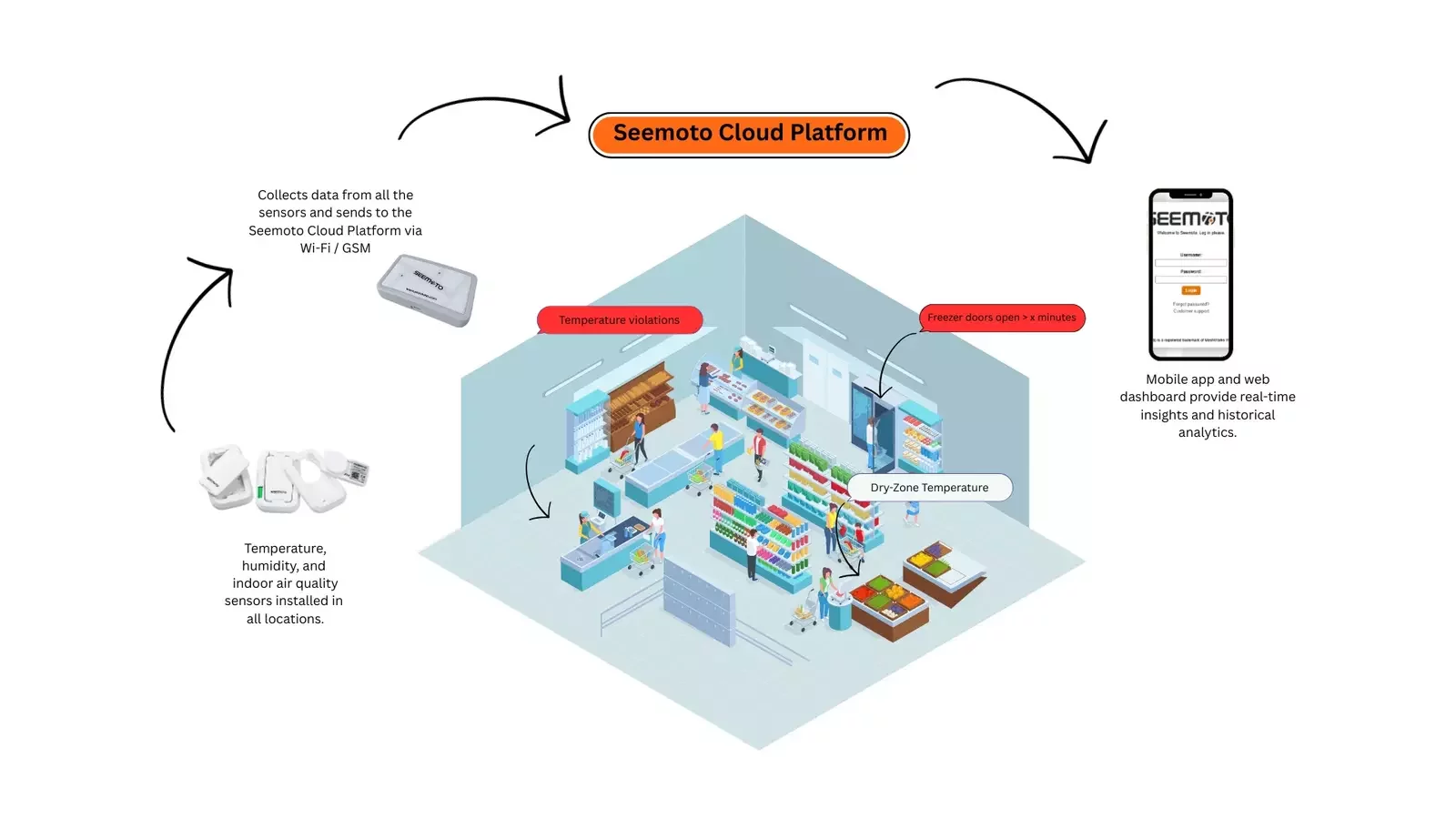

Seemoto provides a fully wireless monitoring solution for cold rooms, freezers, and ultra-low temperature storage, including environments operating down to −196 °C. The system delivers real-time visibility, automated alerts, and audit-ready documentation without complex wiring, manual logging, or IT overhead.

All measurement data is securely stored in the Seemoto Cloud with long-term retention, supporting GMP, GDP, EN 12830, HACCP, and FDA 21 CFR Part 11–aligned workflows.

The Challenge: Why Cold Storage Monitoring Fails Without Automation

Organizations managing cold storage environments typically face the same critical risks:

Manual temperature checks and paper logs

Lead to missed excursions, human error, and incomplete audit trails.Delayed incident detection

Temperature deviations are often discovered too late, after product integrity is already compromised.Ultra-low temperature complexity

Cryogenic and ULT storage requires sensors and validation methods that standard systems cannot support.Audit and compliance pressure

Regulators expect continuous records, traceability, and documented corrective actions.Operational inefficiency

Maintenance teams lack visibility into trends, recurring issues, or equipment performance.

Seemoto addresses these challenges with continuous, automated, and validated monitoring designed specifically for regulated cold chain environments.

A Reliable Monitoring Solution for All Cold Storage Environments

Seemoto enables 24/7 automated monitoring across the full cold storage spectrum:

Cold rooms and walk-in freezers

Refrigerators and medical fridges

−20 °C / −40 °C / −80 °C freezers

Ultra-low temperature and LN₂ cryogenic storage

Industrial process freezers and chambers

Wireless sensors continuously capture temperature data and transmit it securely via GSM/SIM or Ethernet gateways to the Seemoto Cloud. The system requires no fixed cabling, no local servers, and minimal installation effort.

Real-time alerts notify responsible personnel immediately when thresholds are breached, enabling rapid corrective action before product loss occurs.

A Complete Cold Chain Monitoring Platform

Seemoto combines hardware, connectivity, and software into a unified cold chain monitoring ecosystem:

If you manage temperature-critical environments where failure is not an option, Seemoto provides the visibility and control you need.

Application Areas

From Compliance Requirement to Operational Advantage

Seemoto is not only a compliance tool. It provides operational intelligence that helps organizations:

Detect equipment degradation early

Identify recurring temperature instability

Optimize sensor placement and alarm limits

Reduce energy waste and maintenance costs

Standardize cold storage practices across sites

By transforming raw temperature data into actionable insights, Seemoto supports continuous improvement in quality, safety, and efficiency.

Built for Regulated Environments

Seemoto supports compliance with key standards and guidelines, including:

GMP / GDP

EN 12830

HACCP

FDA 21 CFR Part 11–aligned documentation practices

Audit-ready reports, secure data handling, and traceable records ensure inspections can be completed efficiently and with confidence.

Scalable, Easy to Use, and Reliable

Scalable

From a single freezer to global cold chain networksEasy to deploy

Wireless installation with minimal setup effortReliable

Proven sensors, automated alerts, and continuous monitoring

The system is designed to support both day-to-day operations and long-term regulatory compliance without increasing workload.

Commonly asked questions

Ready to Secure Your Cold Storage Operations?

If you manage temperature-critical environments where failure is not an option, Seemoto provides the visibility and control you need.